Want to insure your FBO construction project will be successful? Start with having ‘reasonable’ expectations!

/Editors Note: From time-to-time, FBO Connection bloggers John Enticknap and Ron Jackson invite aviation industry professionals to write a guest blog. For this post we invited Mercer Dye, President of Dye Aviation Facilities, an aviation design and construction management company.

By Mercer Dye

The truth is, most of us in the FBO design and construction business can’t afford the luxury of a guaranteed perfect project - and frankly, no one ever gets one anyway.

As in any endeavor, successful FBO construction projects depend on the owner, or in this case, the FBO owner having reasonable expectations and willingness to participate in the equitable sharing of risks.

I’ve been in the design and construction industry all of my working life. For the past 30 years, my firm has been devoted to the design and construction management of aviation support facilities. These projects range in size from very modest renovations to totally new greenfield projects for FBO’s, aircraft OEMs and large corporate operators. In the hundreds of projects completed, there has never been a lawsuit filed against anyone involved. Not an owner, construction manager, architect, engineer, contractor or material supplier.

I know you can’t see me, but I am knocking on a big piece of wood right now because there is a smidgeon of luck involved in this perfect record. Also, having world class clients who all have become friends really helps.

These successful projects all have a few things in common:

1. Very careful and systematic early project analysis was orchestrated by a General Aviation, Design and Construction Management (DCM) expert.

A. Goals were set based on real needs and the ability to generate a return on investment. Questions included: What is really needed now? How much is it likely to cost? How will it be paid for? How can the project be expanded later?

B. Budgets were NOT set up by the local pre-engineered building contractor. Understandably, this person is in a sales mode and does not have the ability to foresee all potential cost impacts. Remember, a metal building can be less than 50 percent of the total construction cost. Don’t let the tail wag the budget dog.

C. There were careful evaluations of the site conditions by the DCM. Site work can, and often does, cost more than the buildings. Utility availability, soil conditions, storm drainage, pollution control requirements, fire codes, building codes, FAA building limits, zoning or architectural requirements all affect cost and were vetted early. Obviously, this list is very long and overlooking one element can become an ugly surprise later. This is where good industry specific DCM’s can save much more than they cost.

a. The site work and buildings were designed by experts in airport construction and specifically, General Aviation support facilities.

b. A limited list (+/-4) of highly regarded General Contractors was selected to price the design development (75 percent completed) drawings.

c. Contractor selection began with an interview of GC’s, bidder selection and post bid interviews. Then, the selected GC priced the final construction documents. After the pricing was approved, a final contract for construction was negotiated. With the assistance of the DCM, a fair contract was developed between the owner and General Contractor (Cost-Plus Contracts with a Guaranteed Maximum Price [GMP] are most common).

d. The owner had set aside a realistic contingency account established with the advice of the DCM to cover unforeseen costs or extras. Note: There are always change orders, ALWAYS! Well designed and managed projects can have very few.

2. The project, budget, quality and schedule were monitored at regular intervals by the DCM to address issues before they were built into the project or created misunderstandings.

3. The DCM assisted the owner from very early in the design concept stage all the way to turning the key. Through careful team selection and fair contracts, designers and contractors were in partnership with the owner - insuring success.

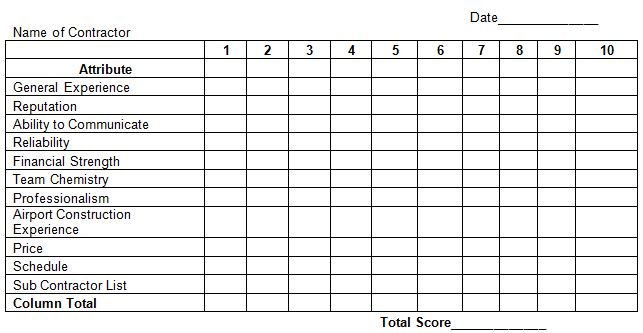

4. Price was not the leading factor in selecting the General Contractor. A post bid grading matrix was used to rank bidders, and aided in making the correct selection. Here is an example:

Therefore, having a successful project is dependent upon:

• Setting appropriate functional and financial goals.

• Selecting the appropriate Design team. Design and Construction Manager (DCM) recommended.

• Conveying your expectations accurately.

• Selecting the right General Contractor.

• Having good weather.

• Not having code officials messing with you too much.

• Not expecting any miracles.

• Having enough contingency money.

• Paying enough attention through the entire process.

Then you can reap the rewards:

• You will have the right facility …

• … of the expected quality

• … at the right price

• … within the expected time frame.

• Your family will still love you, and your employees will still adore you. In short, SUCCESS!

Through all of this, having a General Aviation industry-specific Design and Construction Manager (DCM) is a low or no cost way to get closer to a no risk FBO construction project.

About the author:

Mercer Dye

Mr. Dye is President of Dye Aviation Facilities, an aviation design and construction management company. His experience includes serving as Chairman, CEO and owner of Airway Aviation, a large, Atlanta FBO where he administered the rapid growth and ultimate sale of the FBO to Signature Flight Support PDK.

is President of Dye Aviation Facilities, an aviation design and construction management company. His experience includes serving as Chairman, CEO and owner of Airway Aviation, a large, Atlanta FBO where he administered the rapid growth and ultimate sale of the FBO to Signature Flight Support PDK.

Mr. Dye is an active member of the National Business Aviation Association and the Flying Rotarians. He is a past board member of the Fulton County Airport Association and currently sits on the NFPA 409 Technical Committee for airport facilities. He is the recipient of an American Institute of Architects international honor award presented in Washington, DC by HRH Prince Charles. Mr. Dye is an instrument fixed wing and rotary pilot and is an Army National Guard veteran.

Web site: www.dyeaviation.com